Legacy waste refers to accumulated waste materials that were generated in the past and have not been properly managed, treated, or disposed of. This waste may include various types of materials such as household waste, industrial byproducts, hazardous chemicals, electronic waste, construction demolition debris, and more. Legacy waste can pose environmental and health risks if not managed appropriately, as it may contain contaminants or toxins that can leach into soil, water, or air over a period. Cleaning up and properly managing legacy waste is a priority now to prevent ongoing pollution and mitigate potential hazards.

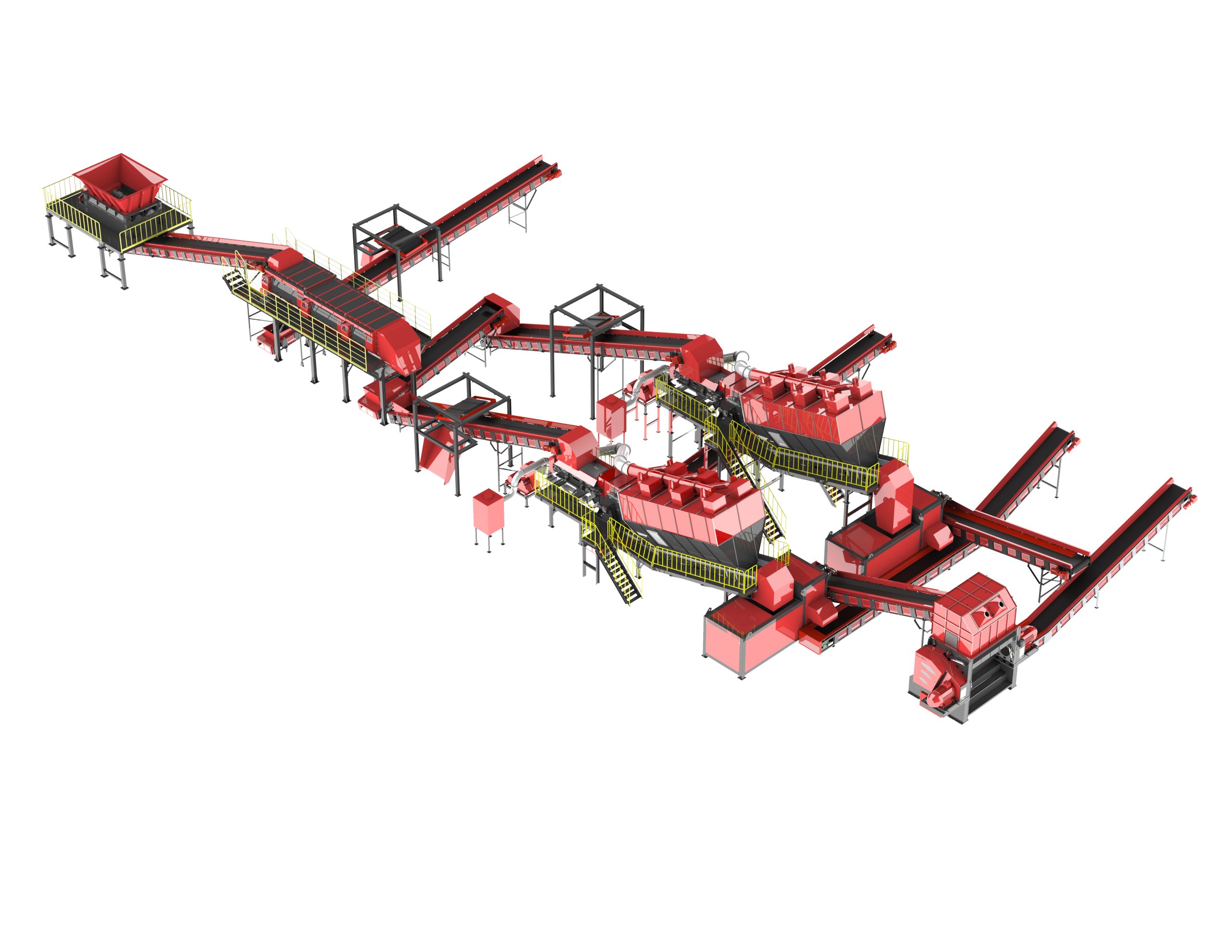

Legacy waste has 25-35% combustible fraction by weight and the rest 65-75% is inert like sand, stone, clay, dust, dirt, metal and other noncombustible material etc. The legacy waste processing facility consists of multiple screening to remove inerts, air density separation or ballistic separator to remove stones and heavy 3D objects, Shredder for size reduction. The recovered combustible fraction is good RDF for cement industry & Waste to energy power plants.