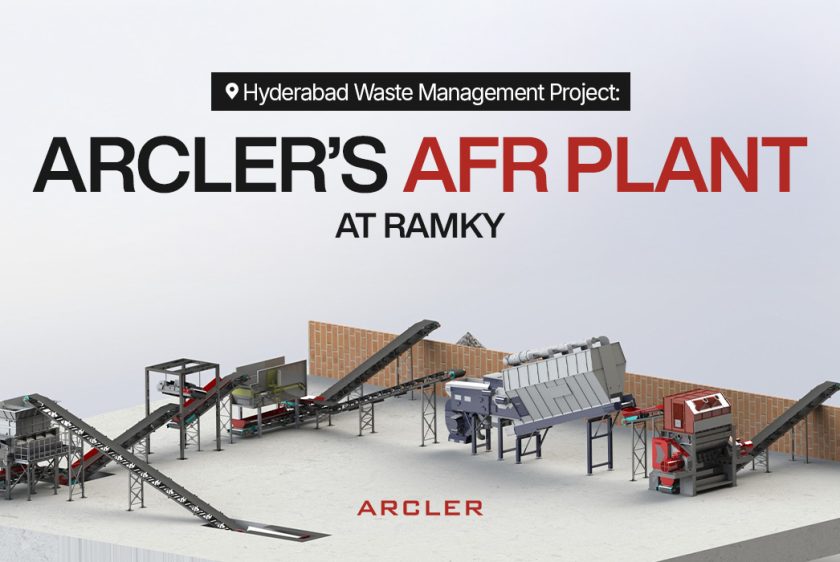

Hyderabad Waste Management Project: Arcler’s AFR Plant at Ramky

Hyderabad, one of the fastest-growing cities in India, generates waste in tonnes per day, ranging from plastic waste and wet waste to biomedical and electronic waste. As the city expands, efficient waste management companies for effective waste management services become crucial for sustainability.

A major step toward effective waste management solutions in Hyderabad is the AFR (Alternative Fuels & Raw Materials) Plant at Ramky, commissioned by ARCLER. This facility is designed to process waste efficiently, convert non-recyclable materials into alternative fuels, and support the city’s environmental goals.

The Hyderabad Waste Management Project integrates ARCLER’s cutting-edge technology with Ramky’s infrastructure, creating a comprehensive waste treatment system. This initiative focuses on:

- Fresh Municipal solid waste processing

- Recovery of valuables

- Compost Fertilizer as byproduct

- High calorific value RDF

By leveraging ARCLER’s expertise in AFR solutions, the plant transforms waste into valuable resources and alternative fuels, reducing landfill expansion and promoting a circular waste economy.

ARCLER’s AFR Plant at Ramky: A Game-Changer in Waste Management

Arcler’s AFR Plant at Ramky is a state-of-the-art facility that ensures the efficient processing, recycling, and conversion of waste into alternative fuels. Through this project, Arcler has enabled Ramky to implement high-performance waste management solutions that align with global sustainability standards.

Key objectives of the AFR Plant include:

✅ Converting municipal waste and non-recyclable materials into RDF

✅ Providing sustainable fuel alternatives to cement kilns

✅ Increasing recycling rates using cutting-edge separation technologies

✅ Reducing CO₂ emissions by replacing fossil fuels in cement production

Arcler’s AFR systems ensure that municipal solid waste, biomass, and non-recyclable plastics are processed into RDF, enabling the cement industry to reduce its reliance on traditional fossil fuels.

Recent Developments in Hyderabad’s Waste Management

High Court Halts MSW Processing Unit

The Telangana High Court recently stopped the construction of an integrated municipal solid waste plant unit in Pyaranagar village due to environmental concerns. (Source: The Times of India)

GHMC’s Technological Initiatives

The Greater Hyderabad Municipal Corporation (GHMC) has launched an advanced Control Command Centre to streamline waste collection and disposal operations, integrating technology-driven waste management solutions. (Sources: The New Indian Express, Hyderabad Mail, Property Adviser)

The Waste Management Process: Arcler’s Role in the AFR Plant

1. Shredding through Primary Shredder

The process begins with the primary shredder, which breaks down large, bulky waste materials into smaller pieces. This initial stage ensures the waste is properly prepared for subsequent screening and processing.

2. Screening through Disc Screen

Once shredded, the waste moves to the disc screen, a key technology used in screening. This equipment separates materials based on size, ensuring larger materials are separated from smaller ones. The disc screen efficiently isolates recyclable materials, such as plastics and metals, for further stages.

3. Wind Shifter for Separating Heavier Material from Lighter Waste

After screening, the wind shifter comes into play, using air currents to separate lighter materials, like plastics and paper, from heavier materials, such as metals and glass. This enhances the recycling process, ensuring materials are correctly categorized for treatment.

4. Fine Shredding of Lighter Waste for Further Size Reduction

Finally, the lighter waste (plastics and other non-decomposable materials) is subjected to fine shredding, reducing its size even further. This ensures it’s adequately prepared for recycling or alternative fuel production. The finer the material, the easier it is to convert into valuable resources like alternative fuels or energy.

AFR Processing: Converting Waste into RDF for the Cement Industry

A key feature of Arcler’s AFR Plant at Ramky is the conversion of non-recyclable waste into RDF (Refuse Derived Fuel) as fuel for cement production. This process includes:

RDF as green fuel for Thermal Substitution

Reduced usage of Fossil fuels

Reduction of CO₂ emissions by replacing fossil fuels in cement production

By utilizing Arcler’s AFR solution ,that minimizes environmental impact while enhancing energy recovery.

Conclusion: How Arcler’s AFR Plant at Ramky is Transforming Hyderabad’s Waste Management

The AFR Plant is revolutionizing Hyderabad’s waste management landscape. With a strong focus on RDF fuel generation for the cement industry, waste-to-energy solutions. this plant is:

🔹 Reducing landfill disposal

🔹 Enhancing RDF production for sustainable cement production

🔹 Reduction of CO₂ emission By integrating Arcler’s innovative AFR technology, the Hyderabad Waste Management Plant sets a new benchmark for sustainable waste management in the city.